Sandblasting for

individual parts or series parts

Maximum flexibility for your projects

With our machinery, we offer you customized solutions for a wide range of surface treatments involving sandblasting. Whether you need to treat large surfaces measuring up to 6000 x 3000 mm or small parts, we have the right blasting system for your requirements.

Why sandblasting?

"Sandblasting is like a targeted fresh

start – thorough, powerful, and the

perfect step before finishing."

Are you looking for a flexible and powerful solution for surface treatment? Our blasting systems are the ideal choice. No matter what material or surface you want to treat, our systems offer fast and thorough cleaning. Thanks to precise control, we achieve a high-quality and uniform surface finish that will impress your customers.

Why you should choose us!

- Many years of experience: We are your expert partner for all questions relating to sandblasting.

- Individual consultation: We find the optimal solution for your requirements.

- High quality: Perfect results.

- Fair prices: Transparently calculated offers.

Sandblasting – thoroughly cleaned, perfectly prepared

Whether old paint, rust, or stubborn residues—with our professional sandblasting process, we reliably remove all contaminants from metal surfaces. But sandblasting can do more than just clean: through targeted roughening, we create the ideal foundation for coatings, paintwork, adhesive bonds, or welding work.

Whether individual parts or series parts: we offer you precise, clean, and uniform results – so that your surface is ready for the next step.

We are your reliable partner

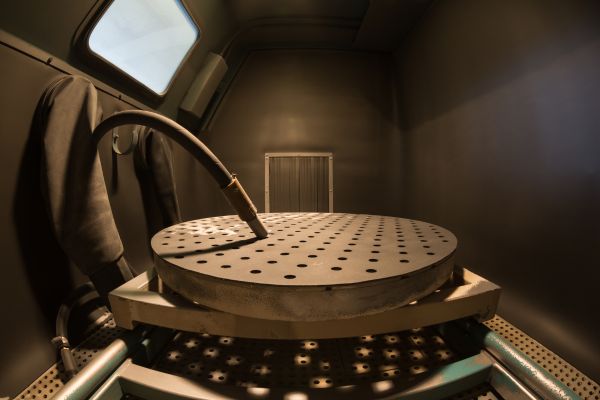

Versatile and effective: our blasting systems

Our blasting systems offer the right solution for every requirement. Whether large-format sheets, rotationally symmetrical parts, or complex geometries - we clean and finish your workpieces precisely and efficiently. From surface blasting systems to manual blasting cabinets - our systems are tailored to your needs.

We have various blasting systems to meet a wide range of requirements:

- Surface blasting system: Ideal for large parts such as sheet metal.

- Steel systems: Specially designed for rotationally symmetrical parts such as pipes or containers.

- Free blasting system: For complex geometries such as car bodies or facades.

- Manual blasting booth: For small and sensitive parts.

Do you have a project? We would be happy to support you.

Looking for high-quality sandblasting services in Thuringia? We are your reliable partner.

FAQ Sandblasting

What is sandblasting?

Sandblasting is a mechanical cleaning process in which surfaces are treated with a blasting agent under high pressure. It removes rust, old paint, scale, or dirt—ideal for preparing coatings or for achieving a uniform surface structure.

What is sandblasting used for?

It is used to clean, roughen, or matt metal parts—e.g., rims, frames, machine components, or sheet metal parts. Sandblasting is also often the first choice for removing old coatings.

What are the advantages of sandblasting?

It is fast, efficient, and can reach even hard-to-access areas. Surfaces treated in this way provide an ideal adhesive base for powder coating, painting, or other coating processes. It also improves the visual appearance.

What materials can be blasted?

Mainly metallic materials such as steel, stainless steel, and aluminum. Castings, tool parts, and complex assemblies can also be machined without any problems.

Is sandblasting also possible for small parts or individual items?

Yes, we process both individual parts and series. Rims, moped parts, or individual workpieces can be blasted quickly and cost-effectively—ideal for private customers as well.